Plastic void former’s can be produced from recycled raw materials, most of the time they are stack-able for easy transport and storage. Foundations built with plastic void former’s have a similar R-value like polystyrene but they maintain their performance unaltered over the time.

Plastic void formers may provide extra protection against moisture from the ground.

Last but not least foundations built with plastic void formers can be more structural efficient and more cost-effective.

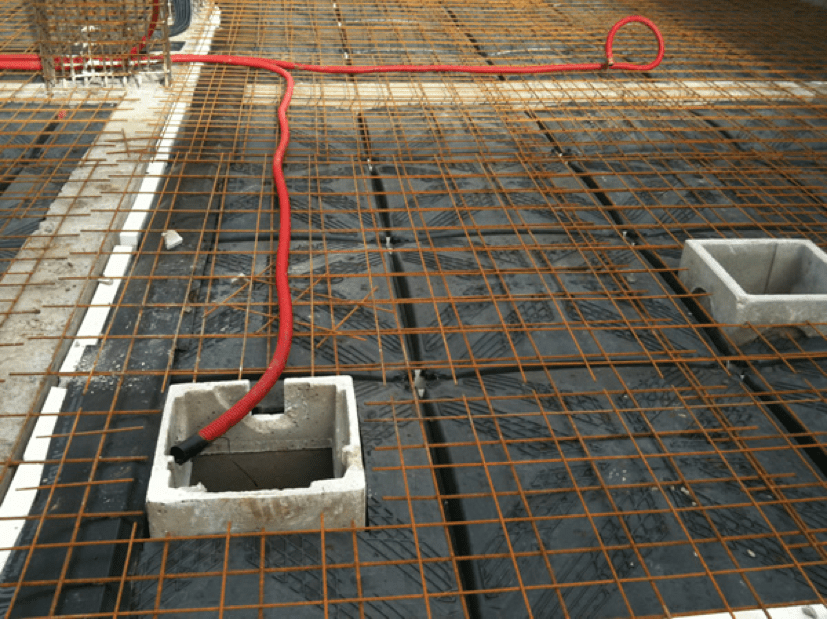

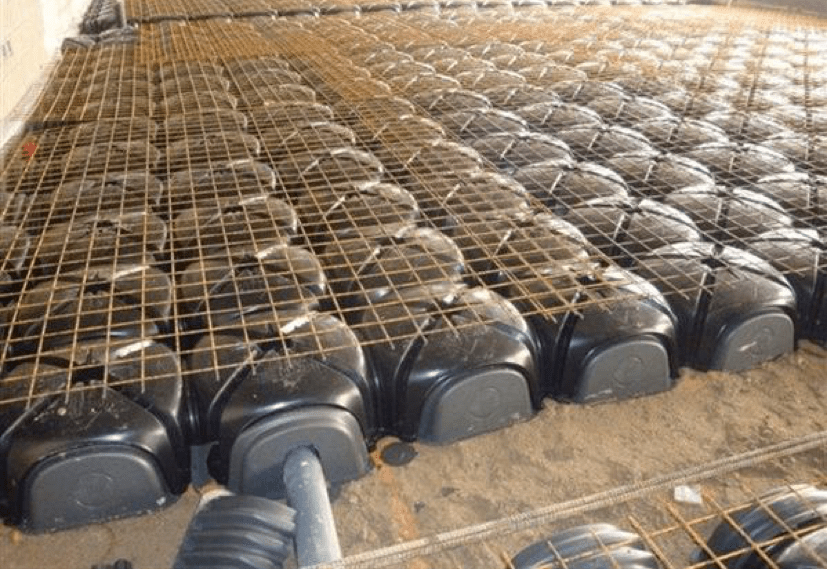

Some examples of foundation technologies incorporating plastic void formers:

Armadillo Foundation System – http://www.armadillo-system.com

Armadillo Foundation System – http://www.armadillo-system.com

RibRaft Xpod – http://www.firth.co.nz/residential/foundations/xpod/

RibRaft Xpod – http://www.firth.co.nz/residential/foundations/xpod/

Sistema Atlantis – http://www.daliform.com/en/aerated-concrete-floor-sistema-atlantis/

Sistema Atlantis – http://www.daliform.com/en/aerated-concrete-floor-sistema-atlantis/

Bubble deck – http://www.bubbledeck.com/

Bubble deck – http://www.bubbledeck.com/

Cupolex – http://www.cupolex.it/

Cupolex – http://www.cupolex.it/

Uboot – http://www.daliform.com/en/disposable-formwork-for-two-way-lightened-voided-slabs/

Uboot – http://www.daliform.com/en/disposable-formwork-for-two-way-lightened-voided-slabs/

Fabio Parodi

CPEng MIPENZ Dott.Ing(ITA) M.Eng(Hons)

CEO and Founding Director of Cresco

www.cresco-group.com

www.cresco.co.nz

1 Comment