Modern polished concrete floors are obtained by grinding and polishing a concrete surface.

Depending on the depth of the grinding and the type of polishing, the surface may show (or not show) the agregates and it may have a matte or glossy finishing.

Polished concrete floors not showing aggregates are an icon of minimalism interior design and they are often used for boutiques, lofts and commercial spaces.

Polished concrete floors with exposed aggregates are a modern interpretation of a grand classic: the “Terrazzo”.

Although the history of terrazzo can be traced back to the ancient mosaics of Egypt, its predecessors come from Italy. The form of terrazzo used today derives partly from the 18th century pavimento alla Veneziana and pavimento alla Genovese. Both pavements had workers place marble fragments next to each other in a mortar base (the marble fragments are smaller for the pavimento alla Genovese).

Pavimento alla Genovese at my company’s office in Genoa (www.cresco-group.com)

It might be because I like modern designs with a vintage feel or it might be because it reminds me my home town but I really love polished concrete floors with exposed aggregates.

I love them because, when they are well done, they are unique, distinctive, hygenic, durable and thermally efficient.

On the other hand, when they are badly done they can look messy, unfinished… a disaster… that’s why I would suggest you to consider the following 12 tips to get the best out your polished concrete floor.

1. Choose the right architect. Polished concrete floors have caracter and they need an appropriate role within your home design. An architect able to emphasize the light reflections on the floor and able to give advice on the available colours and textures (ideally by showing you samples) is a great starting point.

2. Choose the right structural engineer. With a polished concrete floor, a structural element of the building (the reinforced concrete slab) becomes a decorative finishing. Reinforced concrete slabs are prone to crack (e.g. soil subsidence, swelling soils, shrinkage induced stresses…). The choice of a structural engineer with a specific experience in foundation design will ensure a better and a safer result. Let your consulting engineer know that the polished concrete floor is important for you and that you are keen on exploring the best practice to achieve the best result. I am saying this because, without this instruction, your engineer will probably follow the industry standard specifying the most affordable (but not necessarily the best) products and techniques.

3. Choose the right foundation technology. Over the last twenty years conventional slabs on grade have been progressively substituted by waffle slabs with expanded polystyrene (EPS) void formers. Although this foundation system is a good option for your house being stronger and stiffer than a simple slab on grade, it presents a significant drawback for polished concrete floor finishing. In fact, the lightweight EPS beads left within the slab float on the wet concrete during the pouring and they cause damage to its surface.

EPS beads in a waffle slab

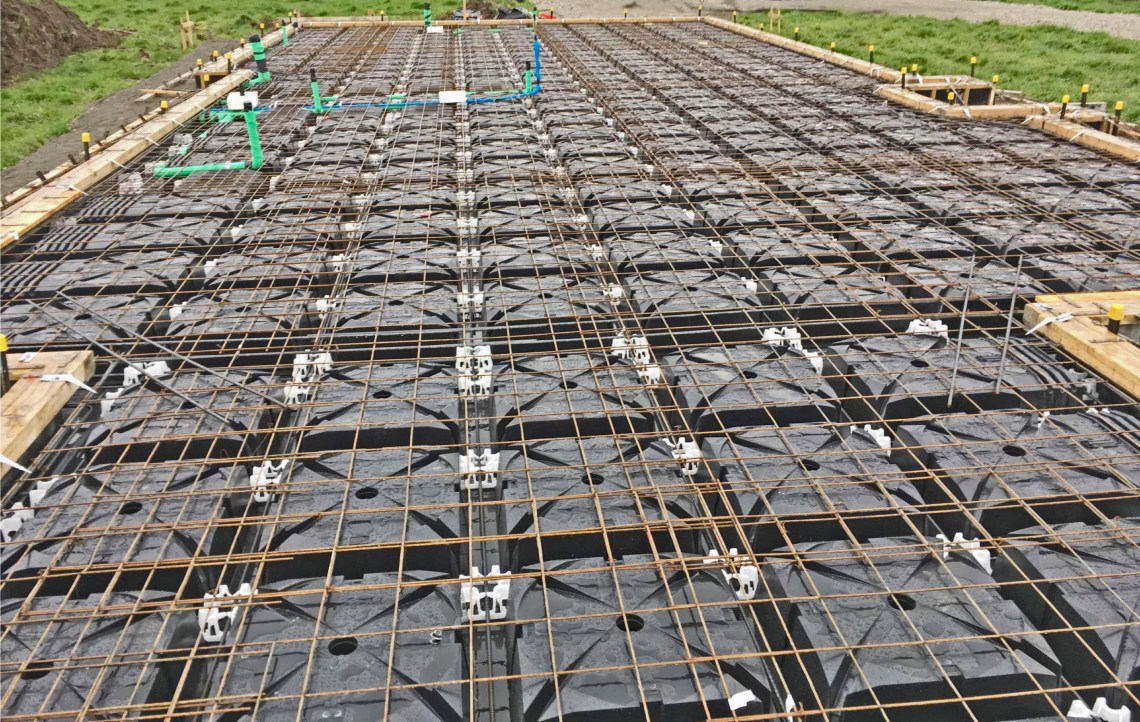

Recently, in order to avoid this problem (and some other issues, see 10 reasons for choosing a Firth RibRaft® X-Pod™), a new waffle slab system using recycled polypropylene void formers has been introduced. Thanks to the design of the RibRaft® X-Pod™ void formers it is also possible to reduce the amount of slab saw cuts although mitigating the risk for shrinkage cracks.

RibRaft® X-Pod™

4. Choose the right contractors. General purposes contractors may not have the skills and the experience for achieving the best results. To engage specialized and reputable contractors (both the foundation installer and concrete polisher) is hence a paramount.

5. Require an adequate concrete recipe. The ingredients of your concrete recipe are: aggregates, cement and water. The appearance of your polished concrete floor (especially if the aggregates are exposed) will depend on the type and size of the aggregates used within the mix. I stronlgy recommend to approve a sample before pouring and to use one source for your cement and aggregate throughout the project. The concrete strength depends on the amount and the type of cement in the mix. A high content of cement (delivering a superior concrete strength than standard, that is to say Fc = 30 MPa instead of Fc = 20 MPa) ensures better results. A low water/cement ratio (achievable by using fluidifiers) is also favourable.

6. Colour. If adding integral colour, use liquid colour or make sure the disintegrating bags are removed from the batch (don’t let them disintegrate in the mix). If your floor will be dyed or stained, make sure your trowel blades are clean and use plastic trowel blades if possible.

7. Consider the use of a secondary reinforcement. A secondary reinforcement like polypropylene fibers will help minimize cracking. Please note: A wrong use of polypropylene fibers may damage the appearance of the polished surface. Expanding agents for shrinkage-compensated concrete may be used instead (or together with) polypropylene fibers.

8. Placing. Plan your pours from the front door to the back door, not side to side. This will put your pour joints front to back instead of side to side, reducing the impact of slight color variation in the different pours.

9. Make sure the concrete cures properly. CCANZ recommendations are clear and detailed on this point. Cracks may occur in concrete construction for a variety of reasons. Indeed, unless appropriate measures are taken to control it, cracking in concrete construction is inevitable because concrete, like most other building materials, moves with changes in its moisture content. Specifically, it shrinks as it loses moisture. Cracks which form before concrete has fully hardened (prehardening cracks) are usually preventable by the adoption of good construction procedures. The most effective way to reduce the risk of plastic shrinkage cracking is to prevent rapid loss of moisture from the surface of the concrete. Practices to achieve this are:

- Dampen subgrade and forms ensuring any excess water is removed prior to placing concrete.

- In hot weather, lower the temperature of the fresh concrete by using cool aggregates and chilled mixing water.

- Erect wind breaks to reduce wind velocity over the concrete surface.

- Use aliphatic alcohols sprayed over the surface prior to and after finishing before curing can commence to reduce rate of evaporation from the surface.

- Commence curing promptly after finishing is complete and ensure the surface is subject to continuous curing.

If plastic cracking does become evident before the concrete has taken its initial set, the cracks may be closed by revibration of the concrete over the full depth of the cracks. This should be done, preferably, by an experienced operator, but a good rule of thumb is to permit revibration of concrete only if the vibrator will sink into the concrete under its own weight. Applying vibration before the concrete has begun to stiffen may allow the cracks to reopen. Applying it too late, ie after the concrete has begun to harden, may damage the bond with reinforcement or reduce its ultimate strength.Surface revibration may be only partially effective as it may not close the cracks to their full depth. They will then almost certainly recur as the concrete dries out. Most concrete, after it is placed, bleeds, ie water rises to the surface as the solid particles settle. The bleed water evaporates and there is a loss of total volume – the concrete has ‘settled’. Revibration of the concrete may help also to reduce settlement cracking. Other procedures which may help reduce plastic settlement cracking include:

- using lower slump mixes

- using more cohesive mixes

- using an air entrainer to improve cohesiveness and reduce bleeding

- increasing cover to top bars

10. Get the surface sealed. Densifiers and sealers should be always applied to polished concrete floors at different stages and serve different purposes. Densification is the application of a liquid silicate hardener to a concrete surface to create a chemical reaction. The densification reaction process fills in the natural pores and voids in the concrete through a process of crystalline growth. The concrete is densified internally and inorganically. The same reaction also hardens the concrete and locks up the dust. After the color (if applicable) and densifier have been applied, a sealer may be applied as the final step. A sealer brings out the beauty of decorative concrete flooring by enhancing the color and the sheen. A sealant also protects the floor surface from abrasions and stains. Note: Some “old generation” sealants may be prone to delamination, scratching, chipping and wear.

11. Cutting. Depending of the size on the shape and on the foundation technology used for your foundation, saw cuts might be required. The purpose for saw cuts is to weaken the surface of the concrete so that if any crack occurs it will be hidded within clean and straight lines. Engineers usually require the floor to be saw cut in a 6 x 6 m pattern. Good engineers limit the saw cuts on areas prone to crack preserving the uniformity and the beauty of the decorative floor. Make your saw cuts before you grind/polish to avoid finish degradation.

12. Slab protection. All trades involved on a job should understand how their spills and traffic can ultimately affect the success of the floor finish. Don’t allow trades to use the slab as a staging or cutting area as this could result in damage to the concrete or differential curing which can leave visible discoloration on the slab.

Fabio Parodi

CPEng MIPENZ Dott.Ing(ITA) M.Eng(Hons)

CEO and Founding Director of Cresco

www.cresco-group.com

www.cresco.co.nz

I appreciate your tip to choose an experienced structural engineer that knows how to deal with foundational issues. My son wants to add polished concrete to his basement in his home. I’ll pass this tip onto my brother so his project can start smoothly.

LikeLike

In Australia our technology has been recently launched under the brand BIAX (www.biax.com.au). I am also happy to inform you that this technology has been recently awarded by NZ concrete socitey as the best New Zeland technology for 2019!

LikeLike